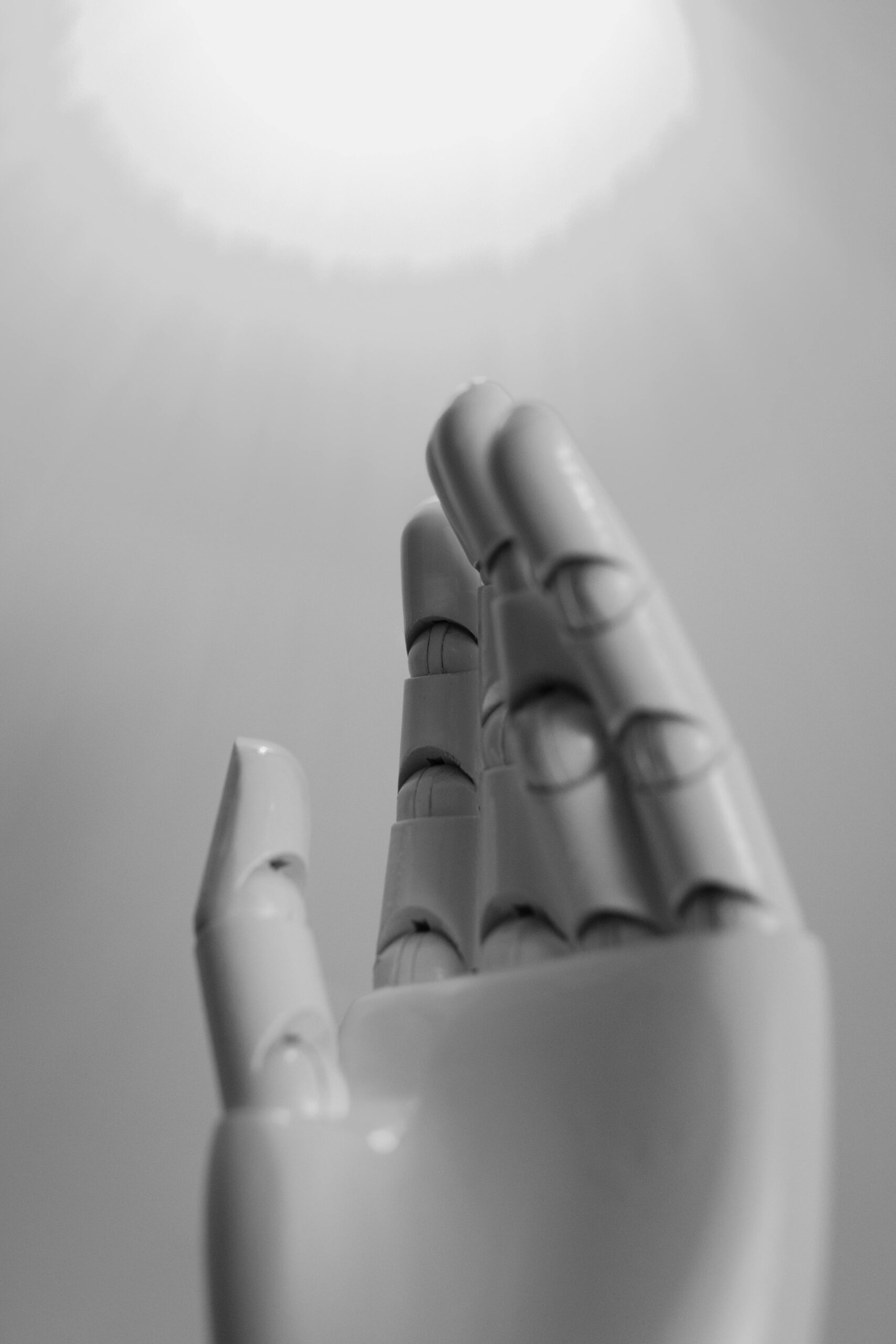

AI & Machine Learning

Artificial Intelligence is at the heart of LeanTex’s smart manufacturing ecosystem. Our AI and machine learning algorithms process vast amounts of industrial data to uncover hidden patterns, predict operational risks, and guide real-time decision-making. From optimizing production schedules to managing complex supply chain logistics, AI ensures that every process operates at peak efficiency. These intelligent systems allow manufacturers to anticipate issues before they occur, enabling continuous improvement and reducing downtime across the production floor.